In ceramic engineering the most common method for producing ceramic components is to form a green body comprising a mixture of the ceramic material and various organic or inorganic additives and then to fire it in a kiln to produce a strong vitrified object.

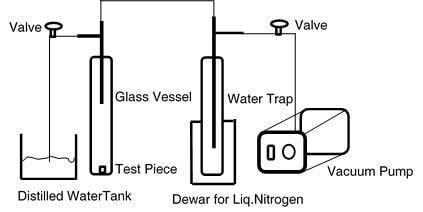

Ceramic density test.

For test samples having an apparentvolume between 50 ml and 100ml a 100 ml cylinder tapped density of powders readable to 1ml can be used.

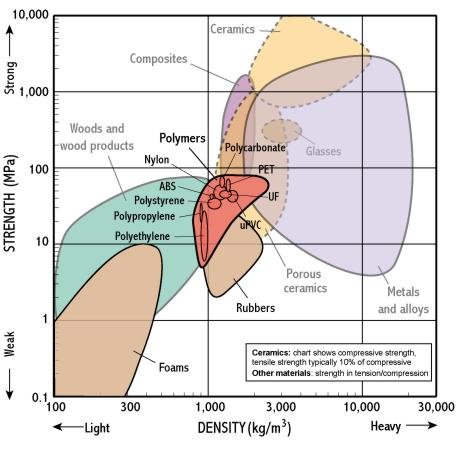

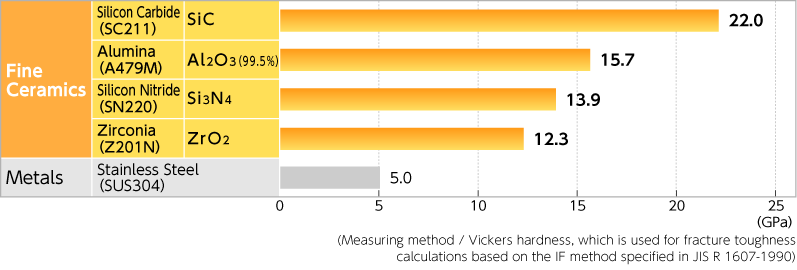

We have collected a number of charts detailing applications and properties for some of the most commonly used ceramic materials.

Official august 1 2015 616 bulk density and tapped density of powders1 616 bulk density and expression of results.

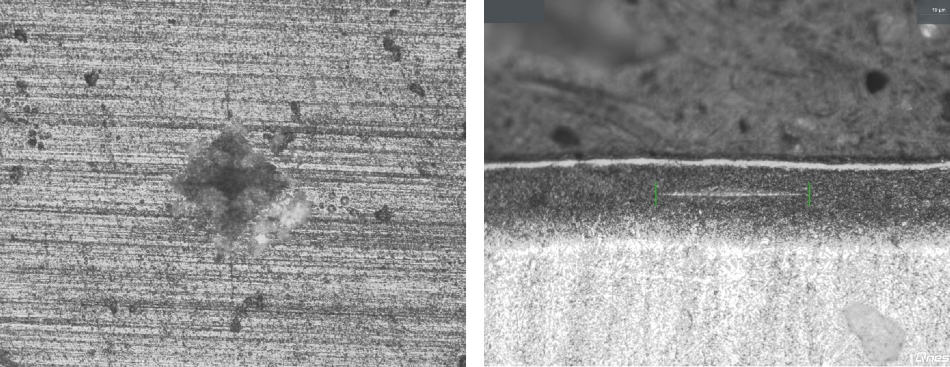

However at 2057 f 1125 c a very slight bloat is evident.

This information has been sourced reviewed and adapted from materials provided by stable micro systems ltd.

Density measurements of ceramics and advanced materials is amongst many other tests that can be performed on stable micro systems physical testing instruments.

The volume of the cylinder is specified in the expression of results.

The ldw test has more information on measuring the density of a dry ceramic.

Standard test method for density of glass by buoyancy.

Or by immersing the uncoated sample in a non.

C729 11 2016 standard test method for density of glass by the sink float comparator.

Thus the density of a powdered mineral is actually referring to the average specific gravity of the tiny particles making up that powder.

Cordierite is a crystalline magnesium aluminosilicate.

Porcelain is a ceramic material made by heating selected and refined materials often including clay in the form of kaolinite to high temperatures.

Ceramics metals slurries pastes pigments plastics mineral matter building materials and other materials can be examined by this method which has density resolution of 0 0001 g cc.

Helium under precisely known pressure is used to fill small voids within a specimen.

C730 98 2013 standard test method for knoop indentation hardness of glass.

Note that the samples are at or very near full density at the two lowest firing temperatures.

While the data in these charts is in most cases typical of what you will find from ceramic component suppliers it is only intended to be a general point of reference and should not be used for material selection or specification.

Each sample fired to a higher temperature becomes more vitrified.

These tests were all made from the same terra cotta body and fired to increasingly higher temperatures.

For more information on this source please visit stable micro systems ltd.

A third kind of density is the apparent density of a dried or fired ceramic body which of course often contains many air pockets.

Using a non contact laser based method.

.jpg)

.png)