The atc recently fabricated the largest ceramic lined nozzle throat insert to date a 5 2 inch throat insert that will be tested with an 800 pound class 1 1 solid rocket motor.

Ceramic engine third nozzle.

For example they are working on significant cost and weight reduction projects across their other engine lines like the leap the ge9x engine for boeing s new 777x.

The metallic components have a preestablished rate of thermal expansion greater than the.

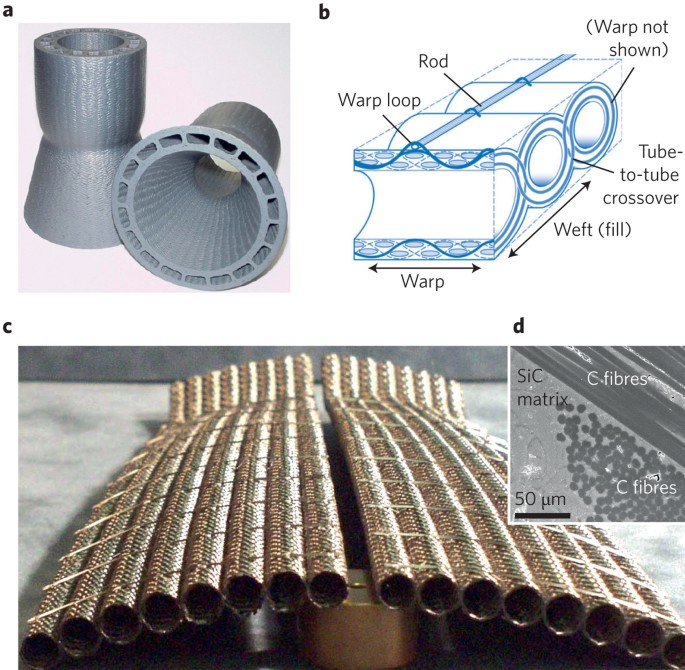

In order to help meet these goals commercially produced ceramic matrix composite cmc components and environmental barrier coatings ebcs are being.

Article osti 415724 title ceramic turbine nozzle author shaffer j e and norton p f abstractnote a turbine nozzle and shroud assembly having a preestablished rate of thermal expansion is positioned in a gas turbine engine and being attached to conventional metallic components.

12 2 4 ceramic matrix composites for gas turbine engine exhaust nozzle with an increase in gas turbine engine operating temperature there is simultaneous increase in the exhaust temperature as well.

Cmcs are one third the density of metal alloys and one third the weight.

Air force research laboratory and industry are partnering to test the ceramic materials as candidates to replace nickel based superalloys currently used in exhaust nozzles.

Oxide ceramics are about one third the density of nickel alloys with similar or even higher temperature capabilities hynes says.

By keeping more air in the flow path instead of cooling parts the engine runs more efficiently at higher thrust.

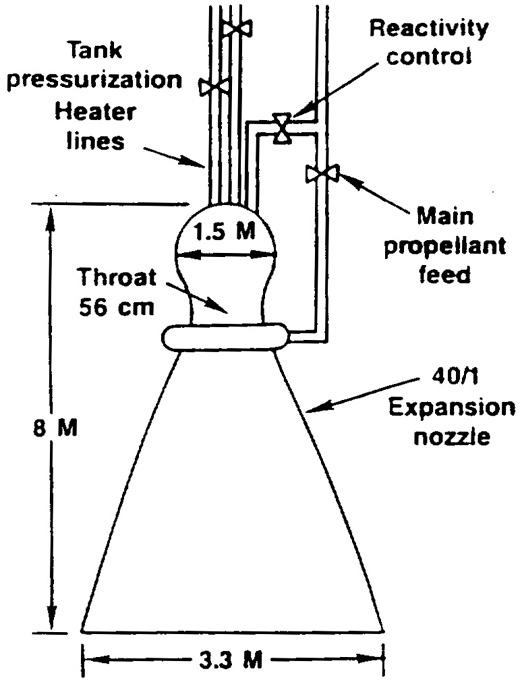

Applications under consideration at the nasa marshall space.

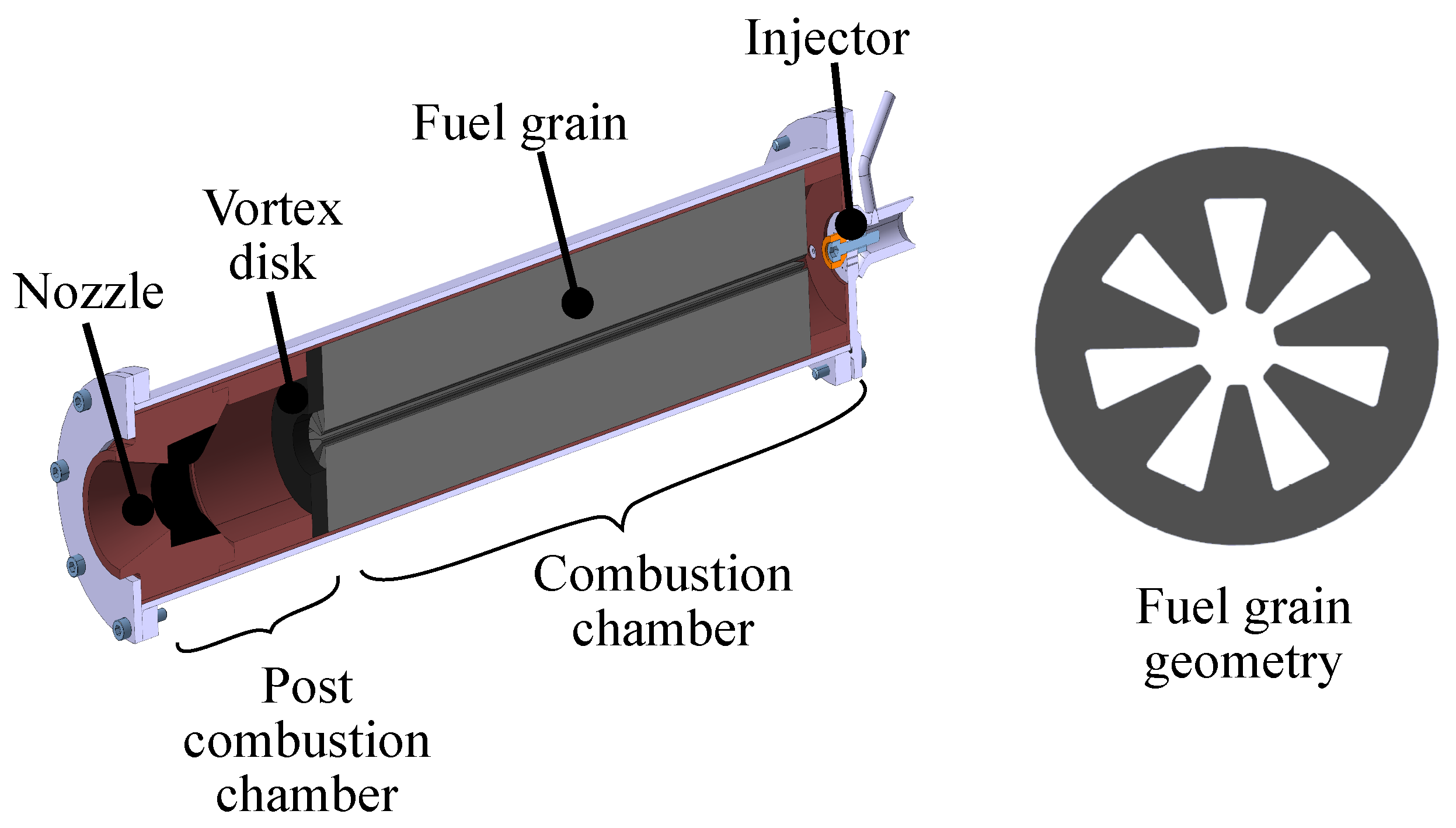

And so alabama s 30 000th 3d printed fuel nozzle takes the facility s fulfilled engine total to around 1 578.

For these the axiom multiaxial prepreg.

An f 16 fighting falcon f100 engine exhaust nozzle with five a500 ceramic matrix composite cmc divergent seals identified by the yellow arrows.

As high efficiency jet engines emit hot exhaust gases they require materials capable of withstanding higher temperatures than titanium and.

The mixer and centerbody are both part of the engine nozzle.

Evaluation of ceramic matrix composite technology for aircraft turbine engine applications the goals of the nasa environmentally responsible aviation era project are to reduce the no x emissions fuel burn and noise from turbine engines.

The exhaust centerbody and the engine core cowl.

Each leap engine produced by ge contains 19 3d printed fuel nozzles.