How we make quality ceramic foam filter and fiberglass fabric mesh filter how we ensure the filters quality ningxin has a unique inside quality control flow that give it a distinct advantage over other foundry filter suppliers which enabling us to deliver the highest available quality of foundry molten metal filters.

Ceramic foam for molten metal filtration.

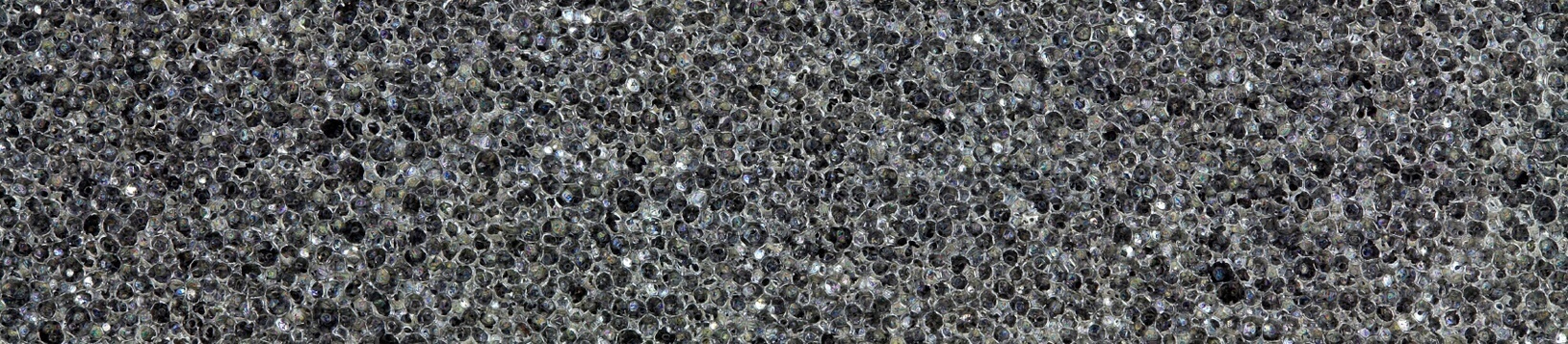

Ceramic foam filter molten metal filtration has great advantages in reducing production costs and improving product quality.

The application of filtration technology in casting has undergone a development process.

Using cost effective metal filtration cup filters simple but very effective to replace ceramic foam filter.

3d printed ceramic filters for molten metal.

The application of filtration technology is a very important aspect of the production of high quality castings.

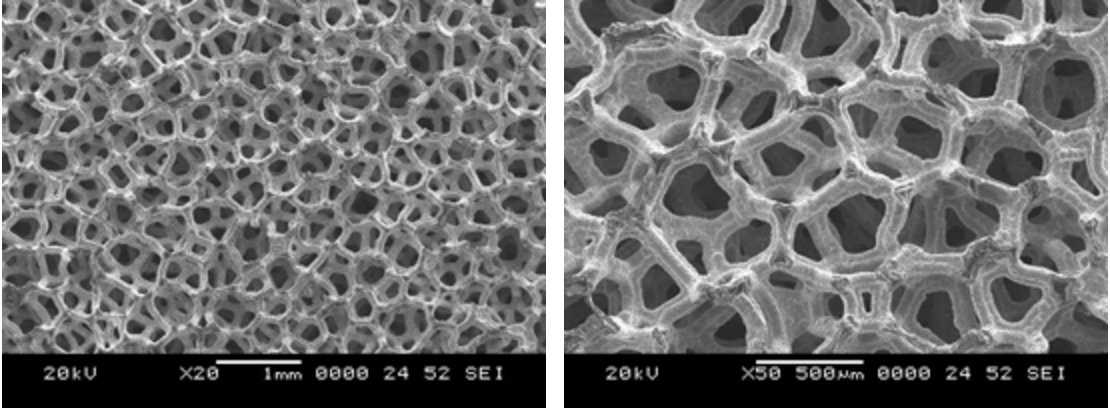

Lattice filters exhibit high strengths reproducible tortuous pathways thermal shock resistance and introduce no debris into the filtrate.

Each filter that we produce is high fired to fully sinter the ceramic body.

The cellular design also provides an engineered balance between flow rate and strength.

Glass fiber filters were used in the 1960s ceramic foam filters appeared in the late 1970s and honeycomb filters appeared in the 1980s.

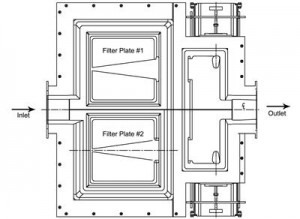

Almex filtrex ceramic foam filtration cff system employs dedicated ceramic foam filter s to remove inclusions which are generated between the refining system and the mold table.

In addition ceramic foam filters are used to purify molten aluminum.

Disa automatic moulding line disa mouding line horizontal and vertical extruded ceramic filter pressed ceramic filter or ceramic foam filter used for molten metal filtration by inserting into filter seat.

The ability of the ceramic foam filter to capture these inclusions is critical to maintaining a clean ingot during the solidification of metal.

Molten metal filtration and distribution during aluminum casting it is common practice to use the filter bag made from the heat resistant glass fiber fabric in order to filter the molten aluminiuim that is being poured through a spout and to distribute it all over the mold surface.

They will not dust or snow to release impurities into your melt.

Extruded ceramic filters can effectively capture inclusions and reduce turbulence of the molten metal mullite based ceramic material could withstand heavy pouring thermal shock and extreme pouring temperature.

Fibrete is proved to be very effective for molten metal filtration in almost all types of aluminium foundries including sand permanent mold shell die casting and investment castings and it will be optimized choice to improve casting quality by using the fiberglass fabric mesh filters.