Demaria insulates the shipping containers with ceramic insulation a spray or paint on system developed by nasa that the supplier claims addresses all three modes of heat transfer radiated.

Ceramic heat transfer media.

Flexisaddle ceramic random media flexisaddle random packing s shape is the most widely used random heat transfer media on the market today.

Echl series liquefied gas stove slice.

We have more heat.

We are a worldwide distributor of rto media offering exclusive distribution of the ceram brand of ceramic heat exchange media manufactured by ibiden porzellanfabrik frauenthal gmbh.

Lexco provides products and design services for regenerative thermal oxidizer systems rtos.

4 0 out of 5 stars 2 027.

Ceramic saddles are mostly used as heat transfer media and are of much higher density and require good high temperature resistance which are made from chemical porcelain and have excellent resistance to acids except in the case of hydrofluoric acid.

Moisture absorption must be less than half a percent.

Sublimation paper heat transfer paper 100 sheets 8 3 x 11 7 for any epson hp canon sawgrass inkjet printer with sublimation ink for t shirt mugs diy.

Cfpw series ceramic filter plate for water treatment.

Because of advances in rto ceramic heat recovery media anguil is routinely able to provide rto operators like tekra with a performance upgrade by either adding to the top of existing media beds or at times replacing the top several layers of existing beds with new extruded ceramic media blocks.

In addition to our unique shapes we offer several technologically advanced ceramic formulations which ensure maximum resistance to corrosion thermal shock and fouling.

Ceramic heat transfer media for rto rco.

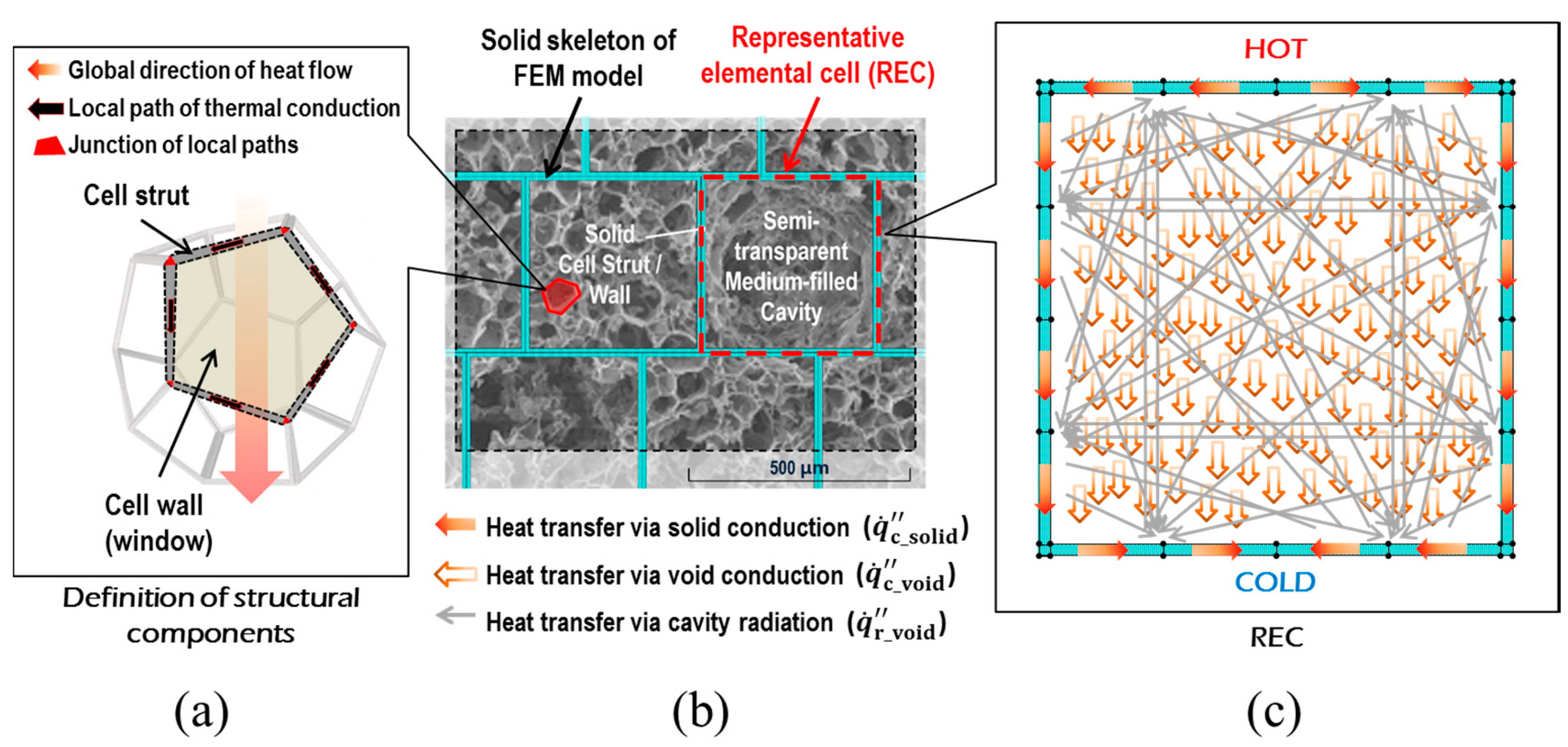

These temperature differences are determined by the thermal conductivity of ceramics as well as the coefficient of heat transfer between the fine ceramic and the cooling media.

1 16 of over 1 000 results for ceramic transfer paper amazon s choice for ceramic transfer paper.

Cfpa series ceramic filter plate for air filtration.

Other ceramic honeycomb series.

These rto use beds of ceramic media christy fill honeycombs and christy fill t 99 to capture the waste heat of combustion and to preheat the combustion air.

In addition the stresses generated are determined by multiplying young s modulus the coefficient of thermal expansion and the temperature differences between the interior and surface of the fine ceramic.

Chh series heat transfer media for rto.

Originally developed for use as a mass transfer packing in acid applications proware material has had good success in heat transfer applications.

Cfpc series ceramic filter plate for cast foundry.

Similarly many melt shops steel aluminum glass etc use reversing regenerative natural gas burners.

Its unique form provides a highly effective surface area and a low resistance to the air flow for mass and heat transfer optimization.