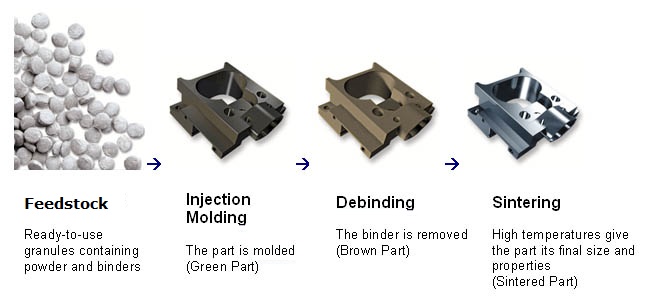

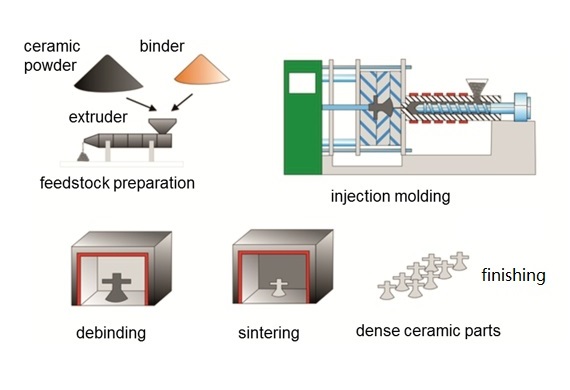

The cim process is a near net shape processing technique that facilitates the low cost manufacture of ceramic components with complex shapes the cim process involves several stages namely mixing injection molding debinding and sintering.

Ceramic injection molding binder.

The binder is used for the artificial plasticisation of the ceramic powders and for the formation of the desired shape through injection molding.

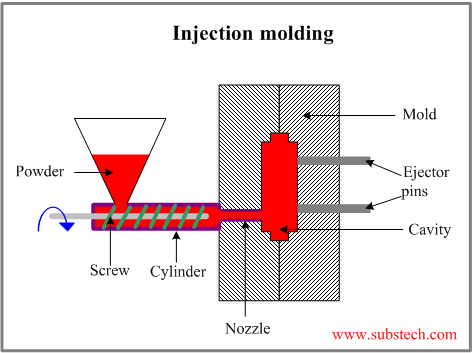

The feedstock is molded using injection moldin g equipment similar to that used for polymer injection molding.

The binder is the most important part of the entire process and has to fulfil several tasks.

Depending upon the part specifications it may be complete after sintering.

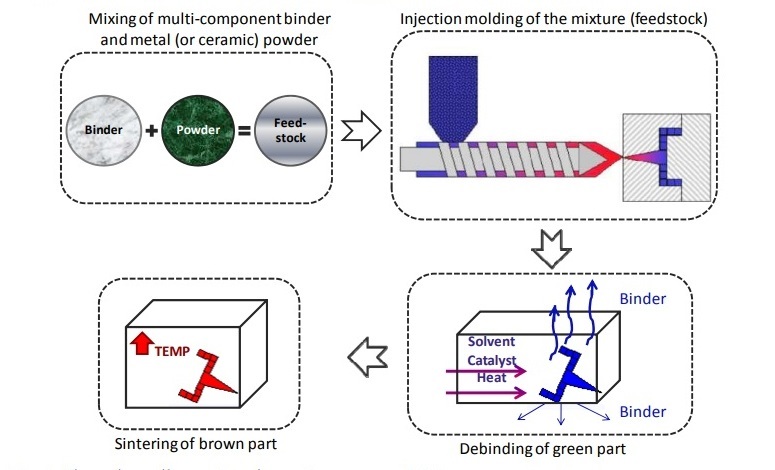

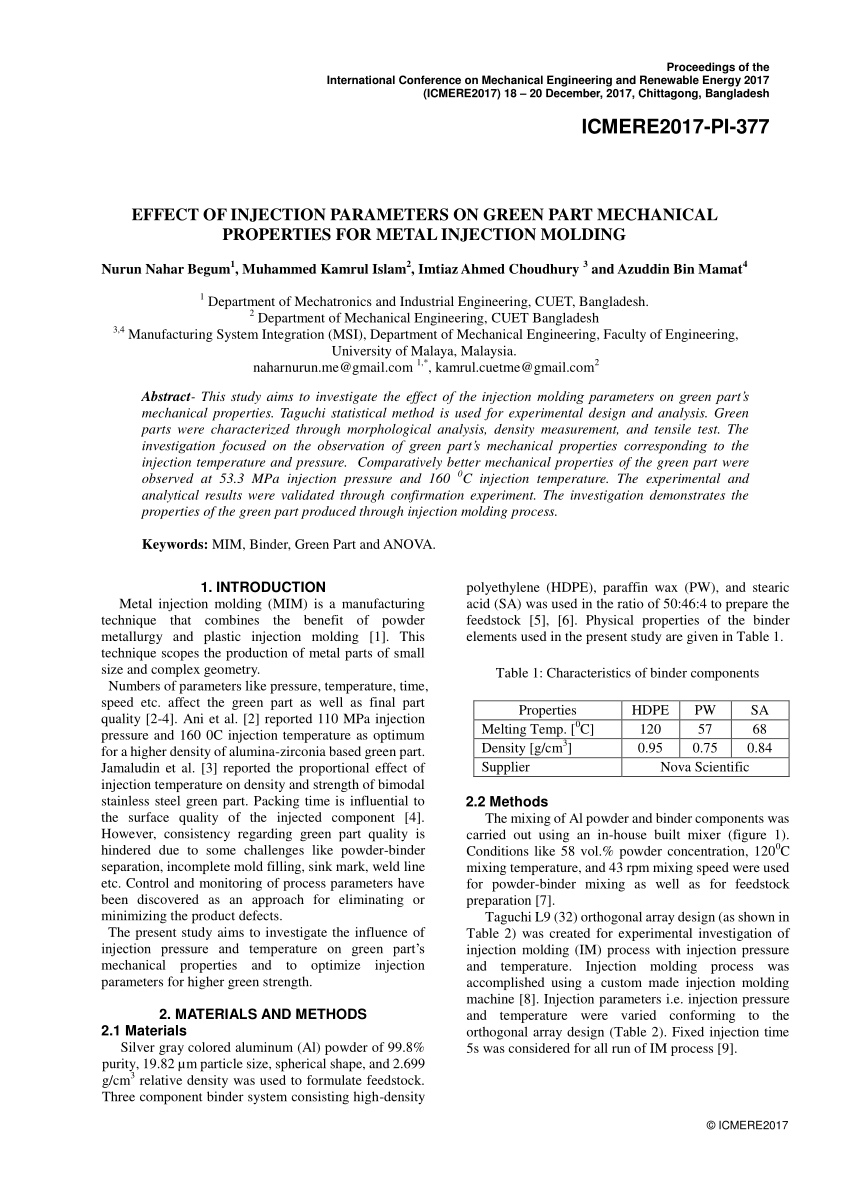

Powder injection molding of metal and ceramic parts 67 the starting material for pim usually termed feedstock is a homogeneous pelletized mixture of metal or ceramic powder and an organic multi component binder.

Be able to incorporate a high volume of fine metal or ceramic powders typically 60 by volume.

The most difficult challenge in the early days of metal injection molding technology was to find suitable binder compositions.

Consideration for binder selection includes the flow characteristics for injection molding the ease of binder removal and binder powder interaction.

Ceramic powders are added to plastic as filler.

But if the part requires more operations in order to meet dimension and finish specifications it then progresses to the.

This procedure removes the last amount of binder leaving only a dense ceramic part.

Cim is also a good option when you need to replace plastic and.

Has optimum ceramic binder content and still maintains sufficien t fluidity rak 1999.

For injection molding of ceramic parts the die must be made of harder and wear resistant metal alloy.

The cim process gives production engineers and product designers more versatility in the use of ceramics as an alternative material with higher productivity lower manufacturing cost s and improved product performance.

Injection molding involves concurrent heating and pressurization of the.

The ceramic injection molding process begins with very fine ceramic powders.

Ceramic injection molding is an innovative new process at indo mim under a six sigma controlled environment.

Binder removal is the most crucial step.

Ceramic injection molding zdravko stanimirovi þ and ivanka stanimirovi þ.

The rotating screw of the injection molding machine shears and compacts the molten ceramic binder matrix further liquefying it the injection molding machine injects the metal binder matrix at high pressure into injection mold tooling part is cooled and ejected molded cim parts now in their green state are de bound where 80 of the binder is.

Using sophisticated mixing technology the powders are compounded with thermoplastic binders to produce a homogeneous pelletised feedstock.

Stage 4 5.

Evaporation or distillation ii.