If you are considering metal injection moulding mim or ceramic injection moulding cim for the production of your components take a look at our extensive design guide for end users.

Ceramic injection molding design guide.

Everything you need to know about metal injection molding all in one guide.

A guide for designers and end users by professor randall german published in the december 2008 issue of pim international.

Akron porcelain plastics company has the advanced technology to produce ceramic injection molding cim components.

Titanium metal injection molding timim smith metal products adds titanium metal injection molding timim capabilities to its mim portfolio of materials that include stainless steels alloys and ceramics.

Metal and ceramic injection moulding.

The cim process gives production engineers and product designers more versatility in the use of ceramics as an alternative material with higher productivity lower manufacturing cost s and improved product performance.

With consistent mixing and forming cim offers superior performance characteristics of ceramics along with the ability to attain extremely tight and uniform tolerances 0.

Ceramic injection molding is ideal for high volume production of complex tight tolerance components.

Ceramic injection molding removing technological barriers for over 100 years from the specialized porcelain labware first made in 1914 to modern electronic devices coorstek uses advanced technology materials and manufacturing capabilities to remove technological barriers for design engineers worldwide.

Ceramic injection molding is an innovative new process at indo mim under a six sigma controlled environment.

A guide to the technology for end users and designers.

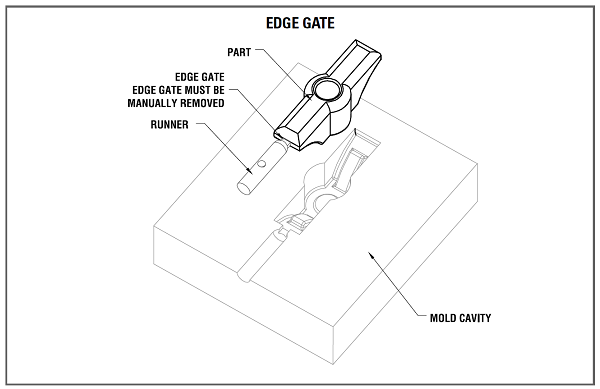

In the world of plastics design for manufacturing dfm is the combination of art science and technologies necessary for designing a plastic part or product prior to tooling and production that will meet customer quality and cost expectations.

Cim is suitable for high volume production of complex ultra precision ceramic parts of various sizes.

A design guide for mim metal injection molding introduction.

It is an effective way of manufacturing complex precision components with the highest degree of repeatability and reproducibility.

Metal powder injection molding mim is a new and revolutionary shaping process focused on forming complex shaped high performance components in large production quantities from metals or even cermets and ceramics.

Cim is also a good option when you need to replace plastic and.

The goal of dfm is to deliver greater levels of customer satisfaction lower production costs and greater profits.