The cim process gives production engineers and product designers more versatility in the use of ceramics as an alternative material with higher productivity lower manufacturing cost s and improved product performance.

Ceramic injection molding wiki.

Metal and ceramic injection molding designing buildings wiki share your construction industry knowledge.

Ceramic injection molding is ideal for high volume production of complex tight tolerance components.

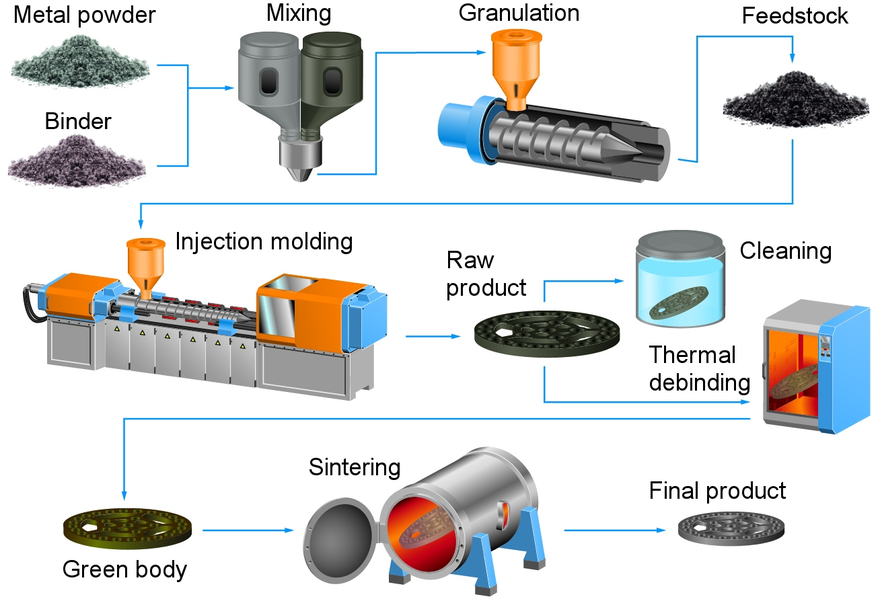

Metal injection molding mim is a metalworking process in which finely powdered metal is mixed with binder material to create a feedstock that is then shaped and solidified using injection molding the molding process allows high volume complex parts to be shaped in a single step.

Cim is also a good option when you need to replace plastic and.

This process also gives a low grade of toleration.

Ceramic injection molding is an innovative new process at indo mim under a six sigma controlled environment.

This itself may have been made using a pattern or model of the final object.

The patterns that ceramic mold uses are plaster plastic wood metal rubber etc the pattern is the shape body of the desired part.

Designs previously rejected as too difficult or expensive to manufacture using other production techniques are made commercially feasible.

Together these two technologies are popularly known as powder.

After molding the part undergoes conditioning operations to remove the binder debinding and densify the powders.

Injection molding is a manufacturing process for producing parts by injecting molten material into a mould or mold injection moulding can be performed with a host of materials mainly including metals for which the process is called die casting glasses elastomers confections and most commonly thermoplastic and thermosetting polymers.

We employ proven techniques and advanced equipment using the strongest and most pure ceramic materials alumina and zirconia.

Metal injection molding mim and ceramic injection molding cim are advanced manufacturing technologies used in the manufacturing of complex precision net shape components from metal and ceramic powder respectively.

Features such as re entrant angles multi shaped blind holes screw threads surface profiles perpendicular holes.

The ceramic molding process is a production method which guarantees the precision required and also gives a good surface finish using a high temperature method to better structure and shape parts.

Molding or moulding see spelling differences is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix.