Our ink systems score highly on adhesion and come in a variety of colours and special effects plus they are scratch resistant dishwasher safe and free of heavy metals.

Ceramic inkjet ink formulation.

Direct ceramic ink jet printing has the advantage that composition is spatially programmable down to the resolution of an ink droplet throughout a component.

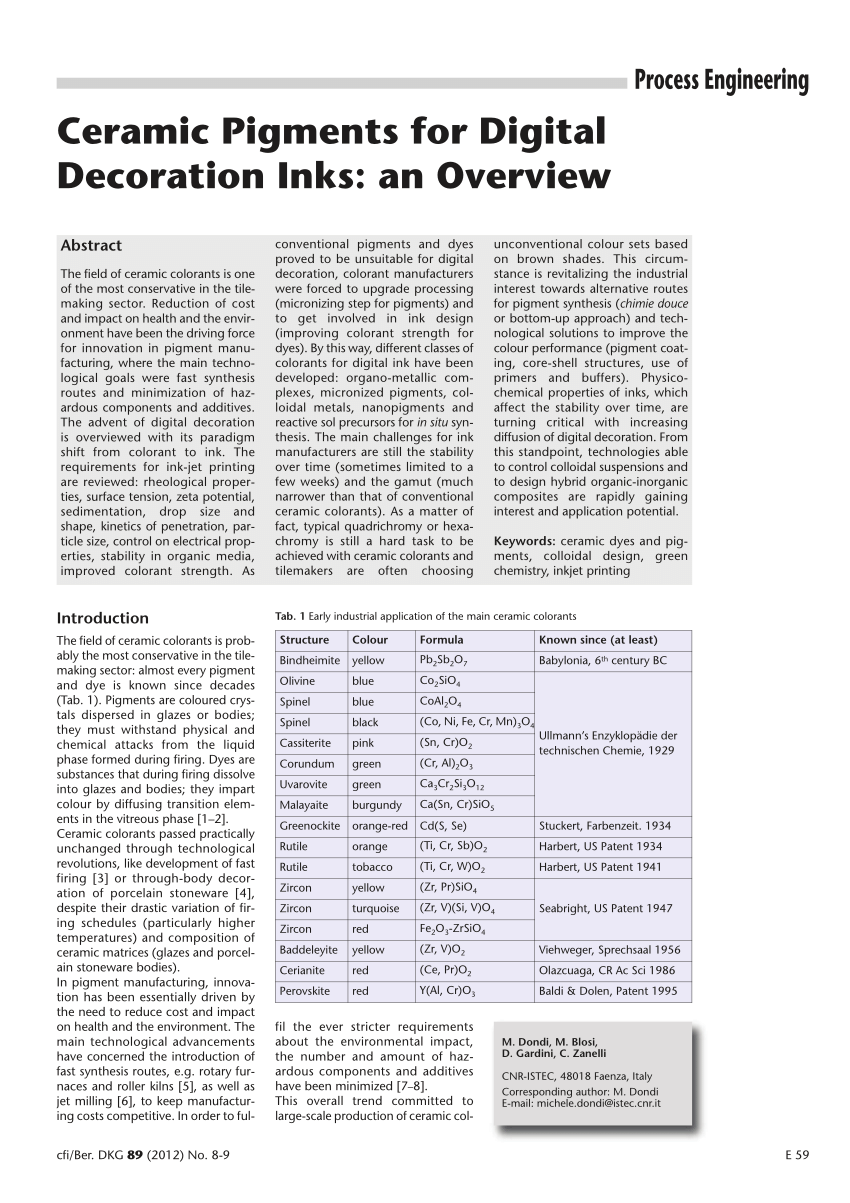

3 and many of them are usable in ceramic ink jet printing 12.

In terms of speed it makes sense to keep the printer running rather than stopping it to switch to a different ink formulation.

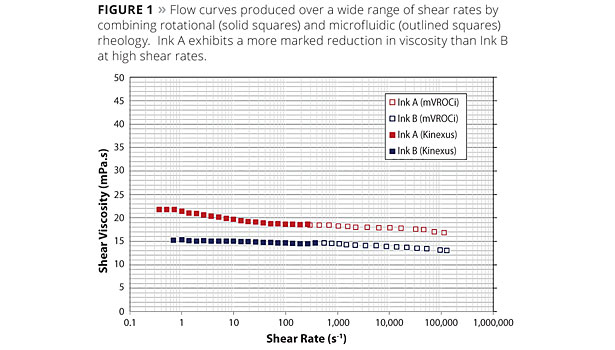

Most solvents used in the formulation of inkjet inks have viscosity in the range 0 5 5 0 cp but inks may be jettable at up to 25 cp or even more.

Marabu specializes in organic inks for glass a highly effective and energy efficient alternative to ceramic enamels.

In one day the printer could be printing on boxes labels plastic cups or ceramic mugs.

The inks were characterised for their rheological wetting and storage stability properties.

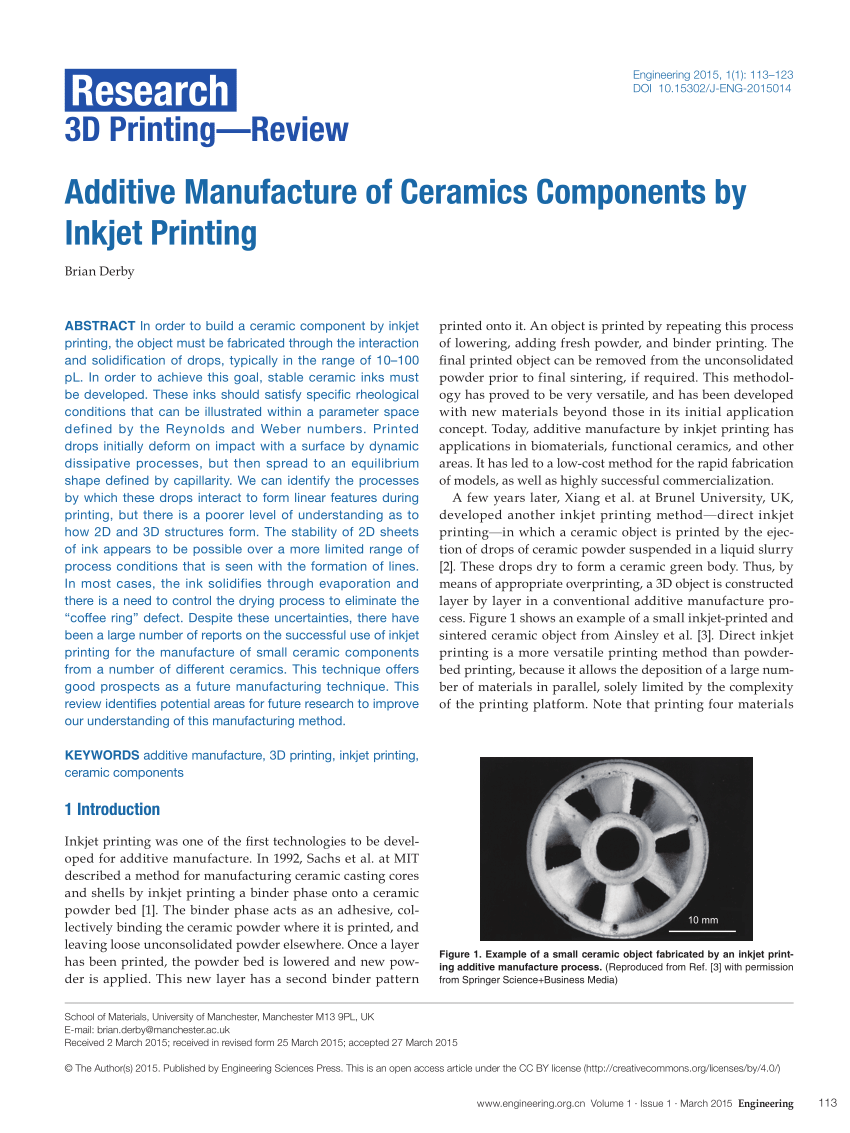

Direct ceramic ink jet printing dcijp process is a suitable freeform fabrication technique to develop ceramic components whose dimensions are in microns.

A lot of materials can be synthesized by the polyol approach table iii and fig.

The primer solution makes sense because the same ink formulation could be used for any of these products.

Various ink formulations were prepared using ci acid red 57 synthetic thickeners byk425 and byk420 ethylene glycol diethylene glycol isopropanol with auxiliaries.

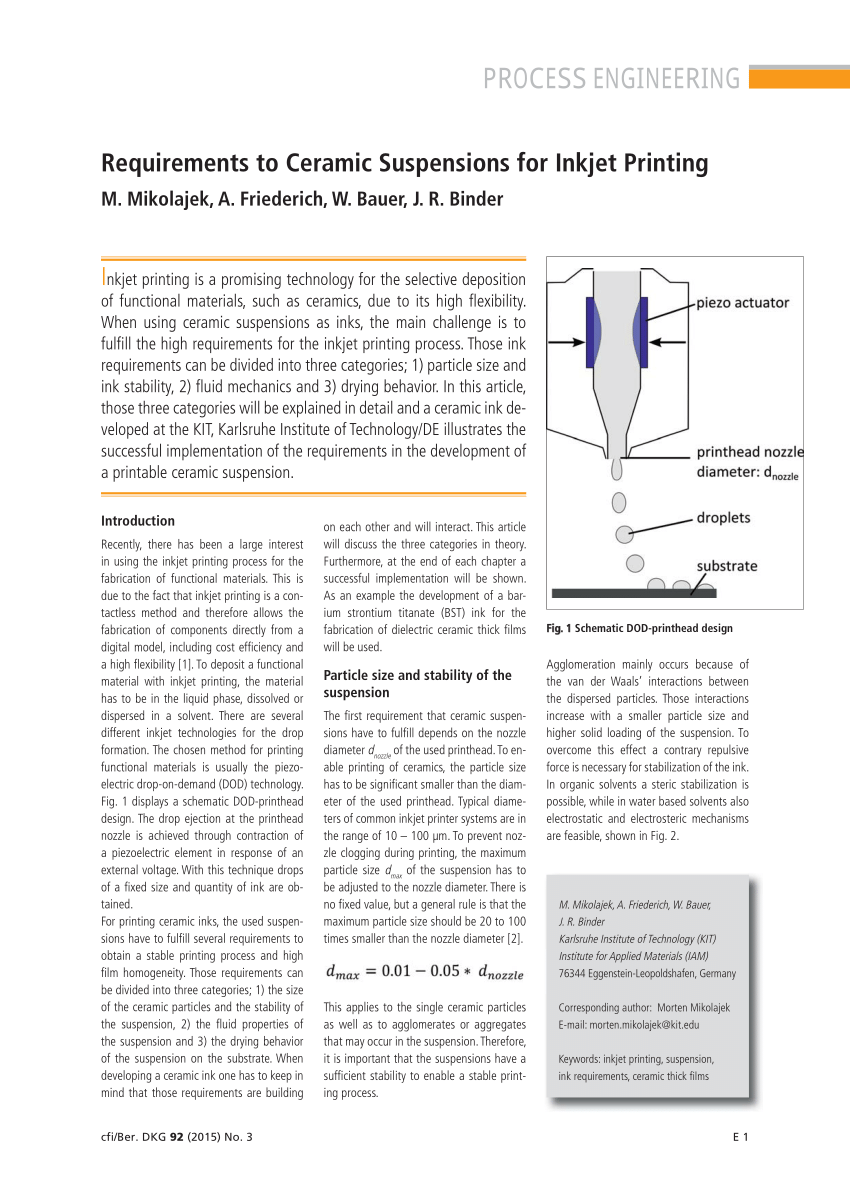

In direct ceramic ink jet printing dcijp ink with ceramic pigment passes through the nozzle to build up a multilayered 3 dimensional structure.

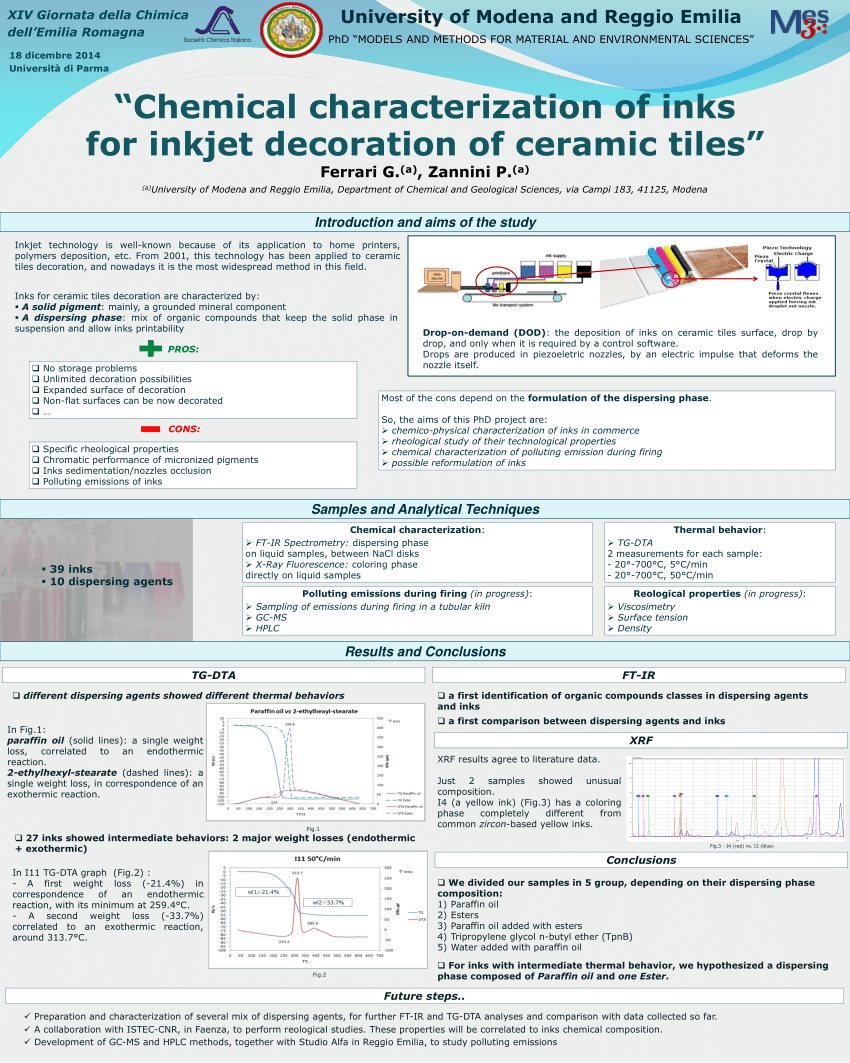

Formulation of ceramic ink the prepared inorganic pigment was micronized using attrition milling to prevent nozzle clogging for the ink jet printing application.

Then the pigment particles were dispersed in a mixed solvent of ethanol and ethylene glycol with addition of cetyltrimethylammonium bromide ctab as a dispersant.

Thanks to the high stability offered by polyol suspensions the solid content of inks can be as high as 20 by weight so ensuring optimal colour performance.

The ceramic mixture 2 2 dimethyl 4 hydroxymethyl 1 3 dioxolane commercially available from rhodia 69457 lion france under the trade name augeo sl 191 has a viscosity of 11 cp.

.jpg)