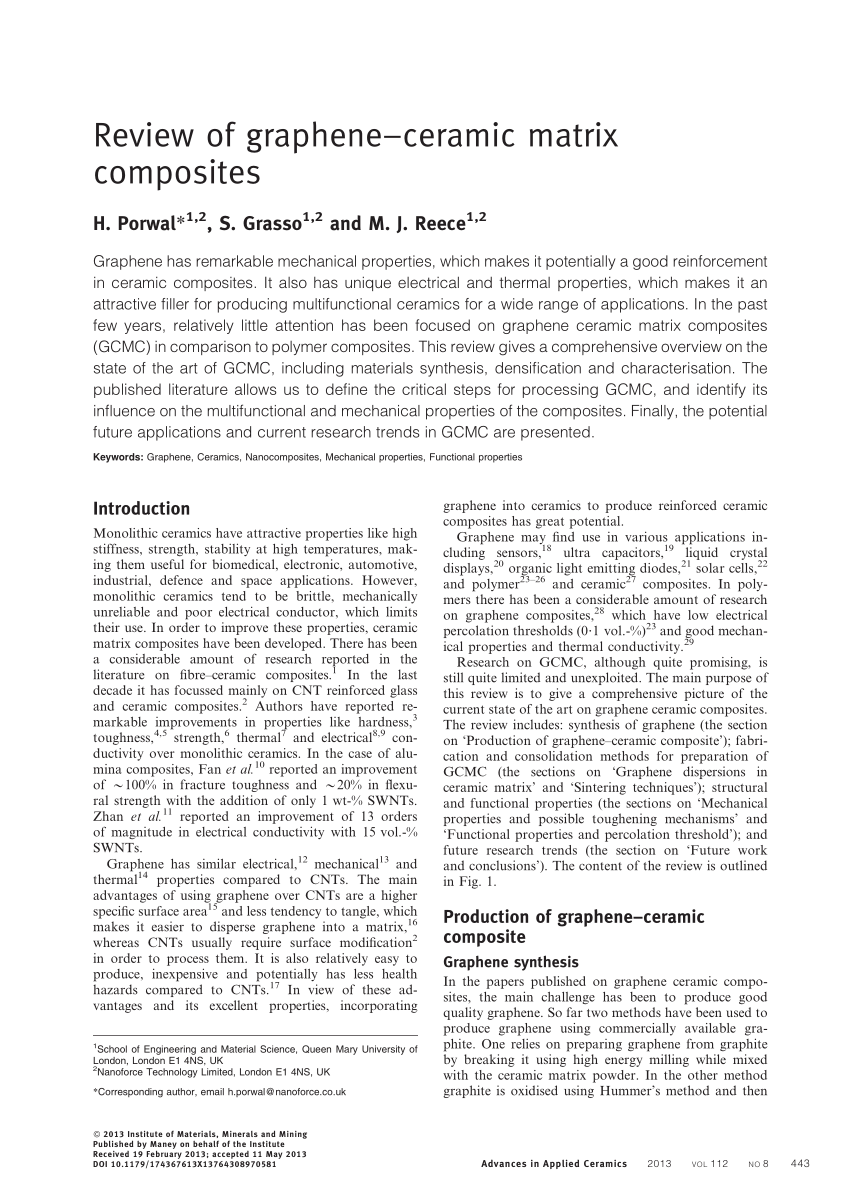

Axiom materials is the world s largest producer of oxide oxide ceramic matrix composite pre preg materials.

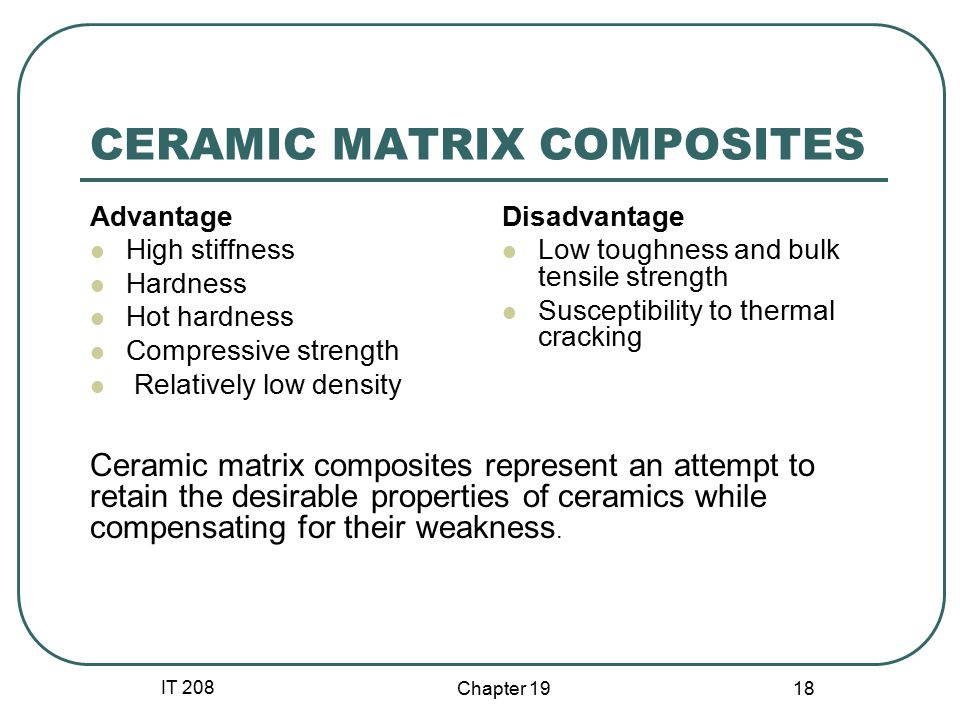

Ceramic matrix high processing temperature manufacturing.

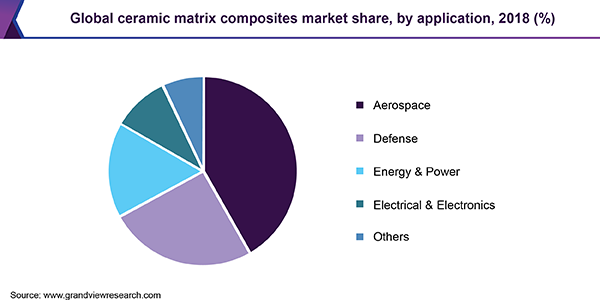

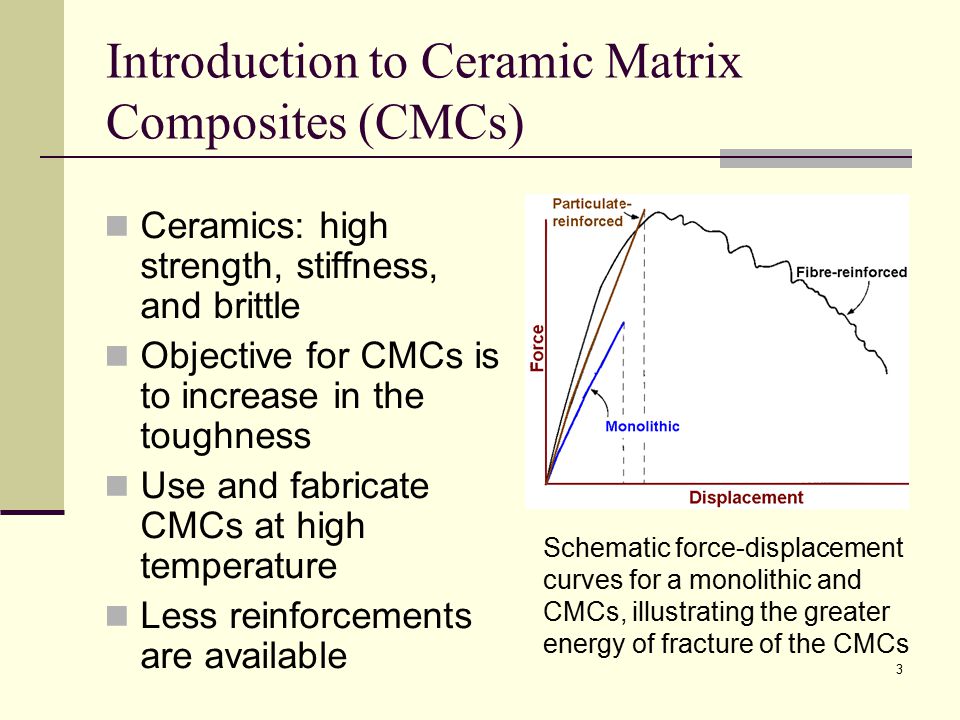

Oxide ceramic matrix composites o cmc combine high temperature stability low density high strength and good corrosion resistance with a.

Pdcmcs are suitable for wear resistance corrosion resistance high temperature ultra high temperature applications.

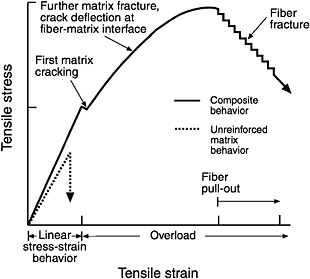

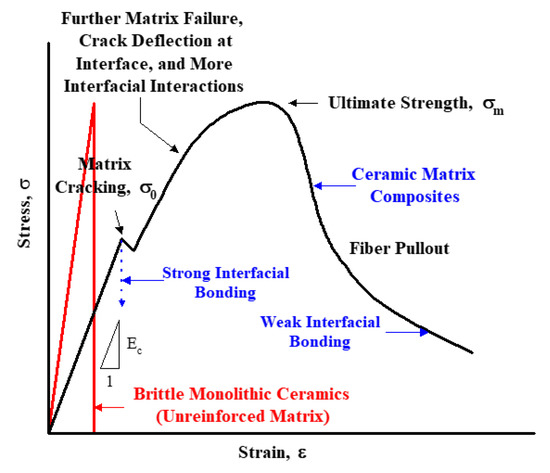

Damage tolerant quasi ductile fracture behaviour enabling a variety of applications with demanding.

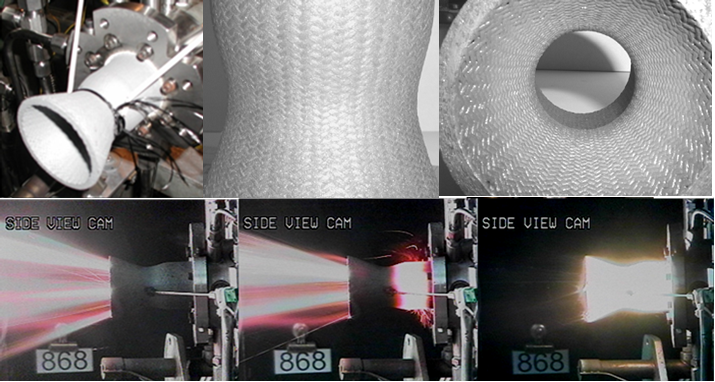

C sic high braking performance low weight 2 4 g cm 3 low wear rate operating temperatures 1 400c first studied in 1990s available in 2000s mercedes cl 55 amg f1 lim.

Additive manufacturing of tailored macroporous ceramic structures for high temperature applications.

The crystallinity of ceramic materials ranges from highly oriented to semi crystalline vitrified and often completely amorphous e g glasses.

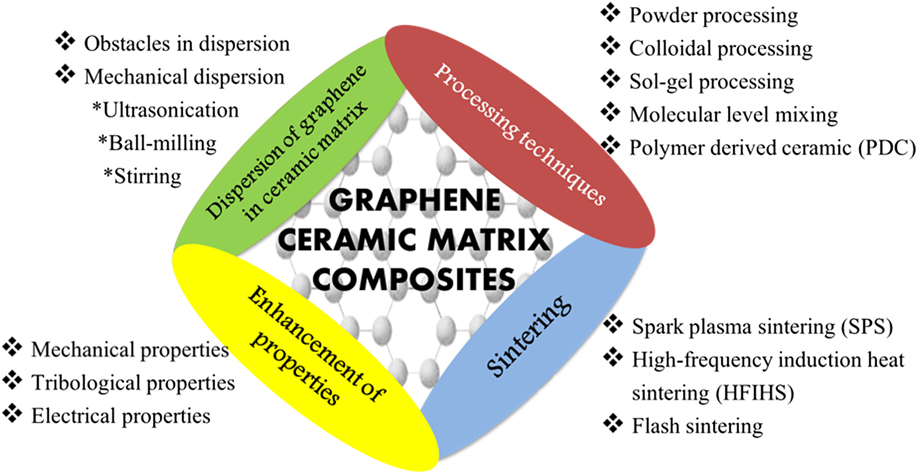

They can also be amorphous or have inhomogeneous chemical composition which develops upon pyrolysis of organic precursors the high process temperatures required for making cmcs preclude the use of organic metallic or glass fibers only fibers stable at temperatures above 1 000 c 1 800 f can be used.

Common examples are earthenware porcelain and brick.

If cmc with higher operating temperatures and.

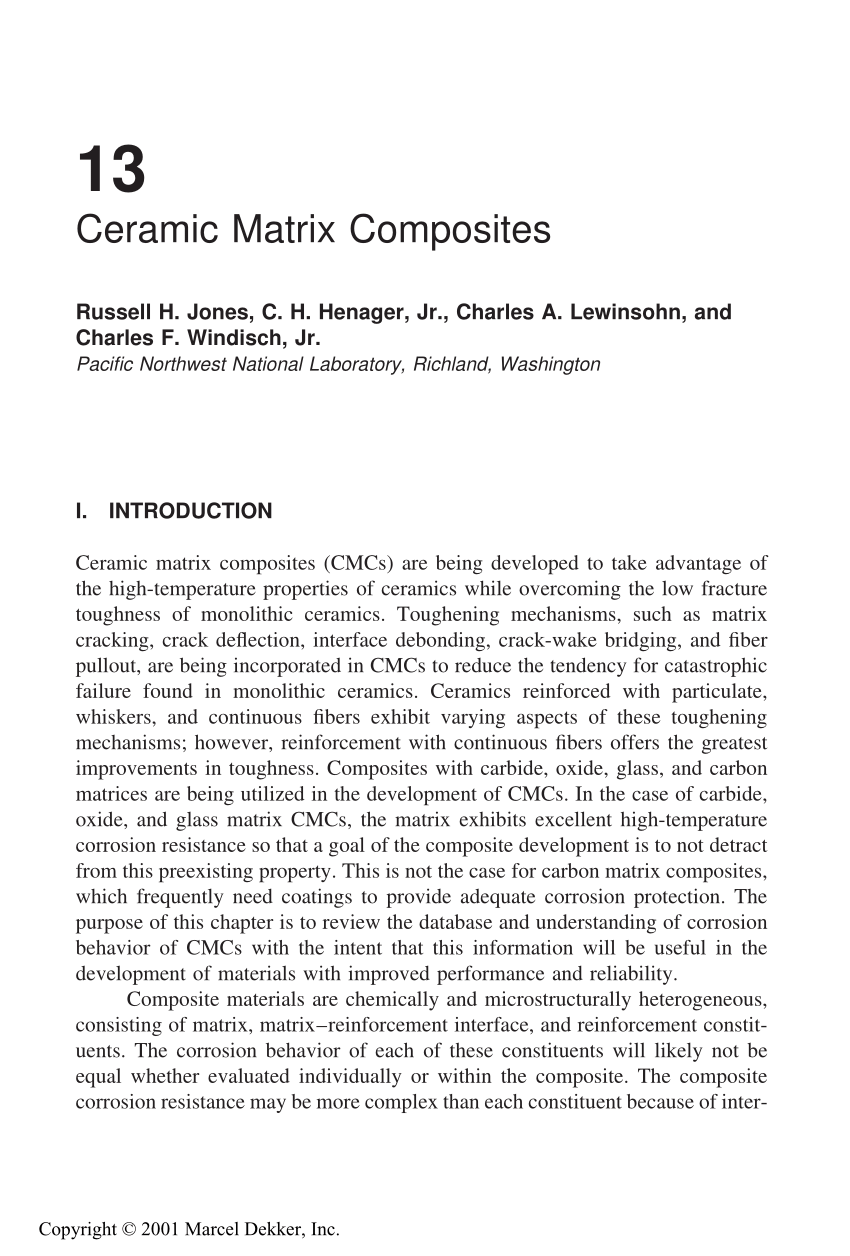

Here we outline work in the last dec ade on the processing of uhtcs with a reinforcing fiber phase for enhanced fracture toughness.

World leader in ceramic matrix composites.

Included are fibers of both carbon and silicon carbide composition in.

Oxide ceramic matrix composites manufacturing machining properties and industrial applications.

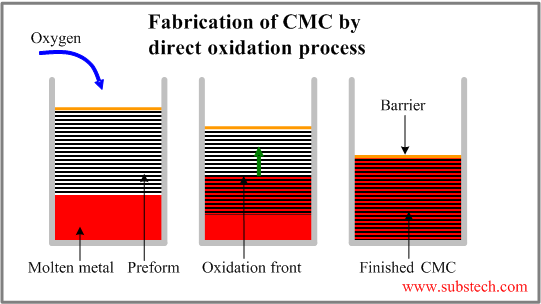

Today the only process for achieving very low sic sic matrix porosity involves a final step of high temperature infiltration of molten silicon but this limits current cmc use temperatures to below 2400ºf due to poor creep resistance caused by residual silicon in the matrix.

Ceramic fibers in cmcs can have a polycrystalline structure as in conventional ceramics.

Ramic matrix composites uhtcmcs offers the toughness benefits of a composite with the high temperature stability of uhtcs.

Hence this economic method is suitable to replace commercially available high pressure processing method as well as long duration processing method to produce carbon fiber reinforce ceramic matrix composite.

Ceramic composite brakes.

2000 porsche 911 gt2 2001 pccb 50 000 70 000 cmc brake discs manufactured in 2006 sicom brembo.

Range of achievable thermal conductivities for a single material is demonstrated with tuning of the fabrication process.

The rmi process is often chosen as it is rapid and can be used with various geometries to efficiently fill both large and small porosity to create a dense matrix.

High matrix density is especially beneficial in an oxygen containing environment at ultra high temperature over 2000 c to prevent oxygen diffusion from advancing deeper into.